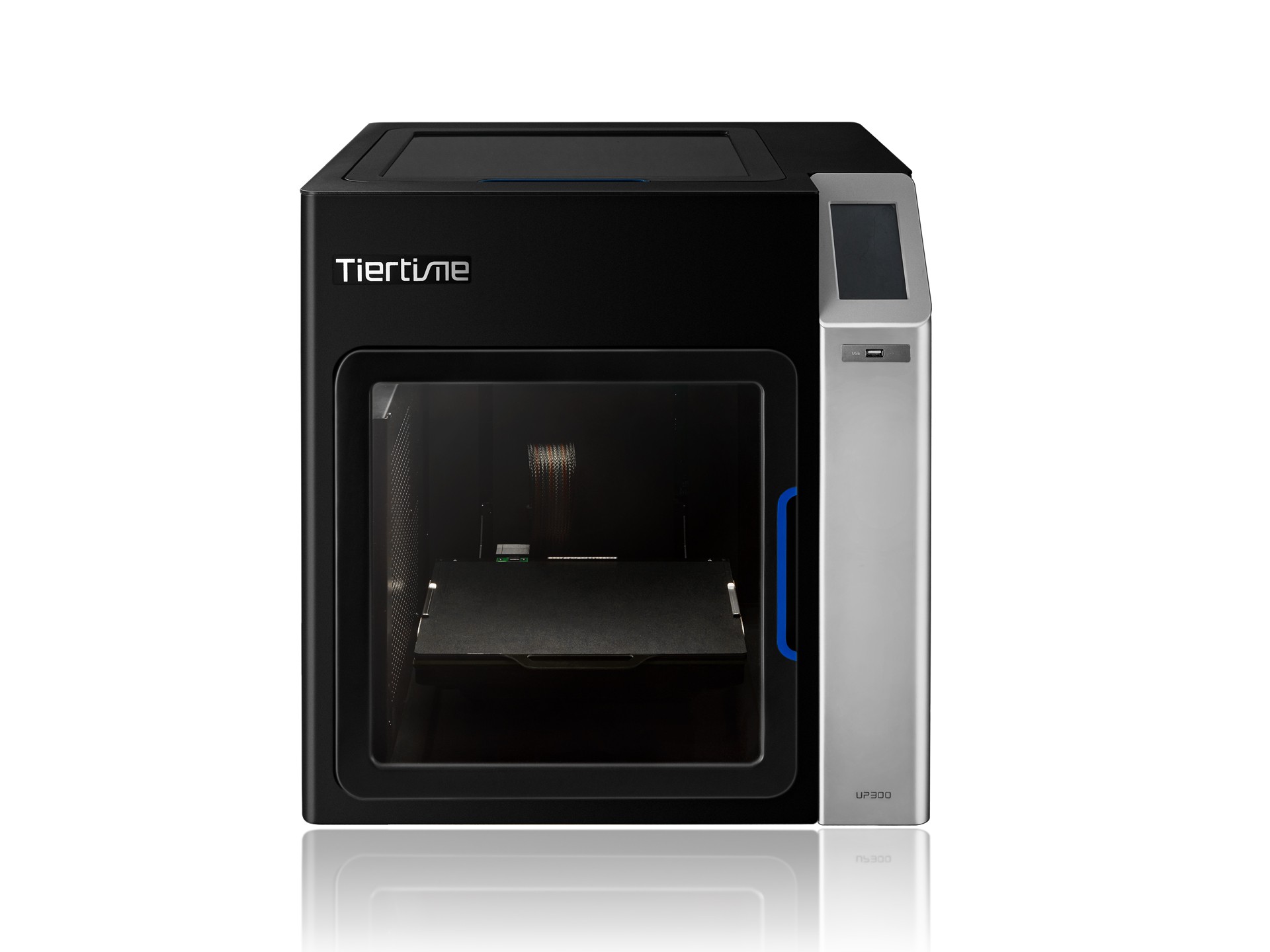

Massive Capacity

Print large objects, with a build capacity of over 13 litres.

Touchscreen

Activate prints, change settings, calibrate and more using the colour touchscreen.

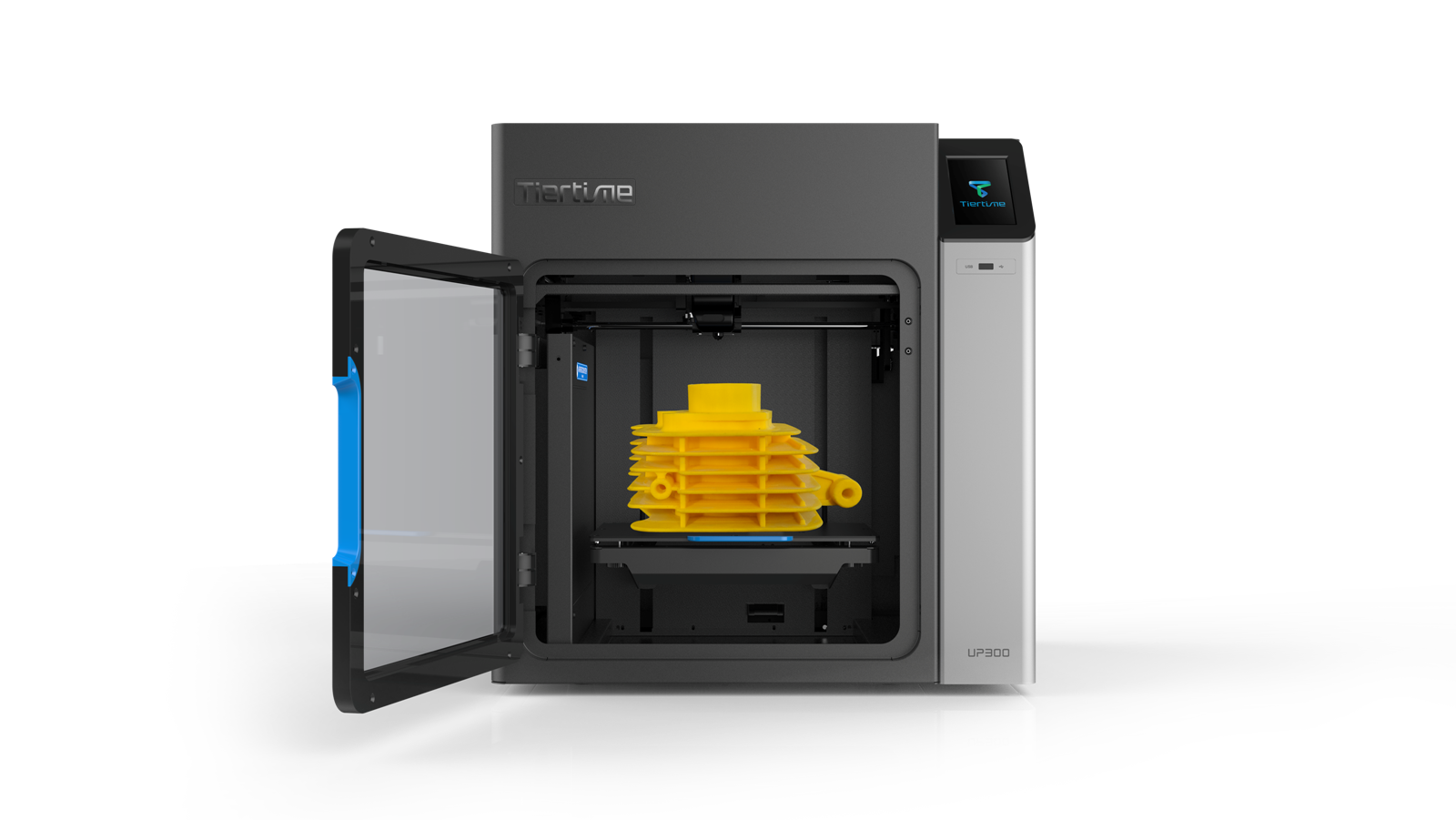

Waste Tray

A removable waste collection tray is positioned below the build platform to make cleaning the bottom of the printer’s enclosure a breeze.

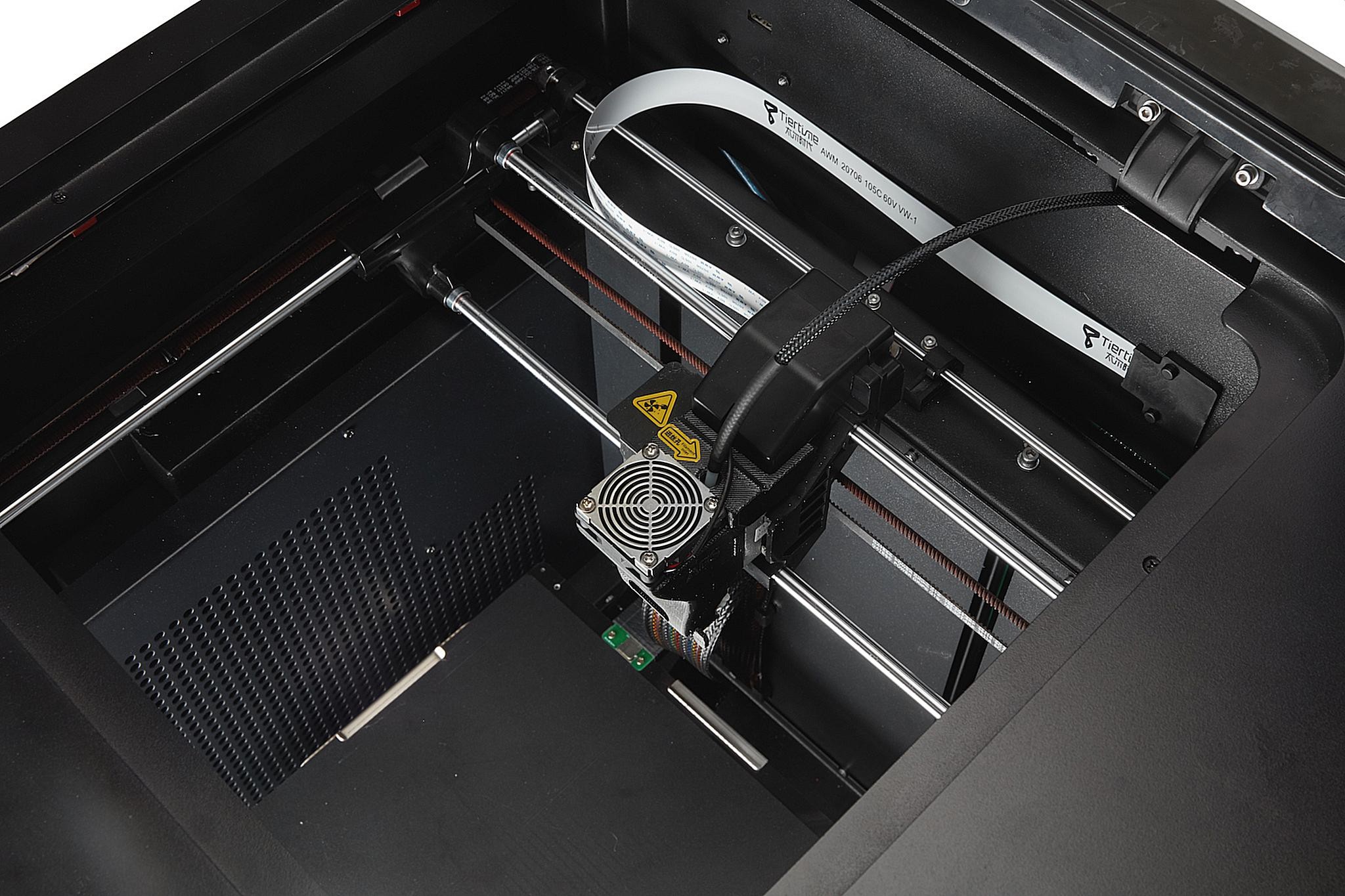

Swappable Extruders

The printhead can be swapped when changing materials for the best print.

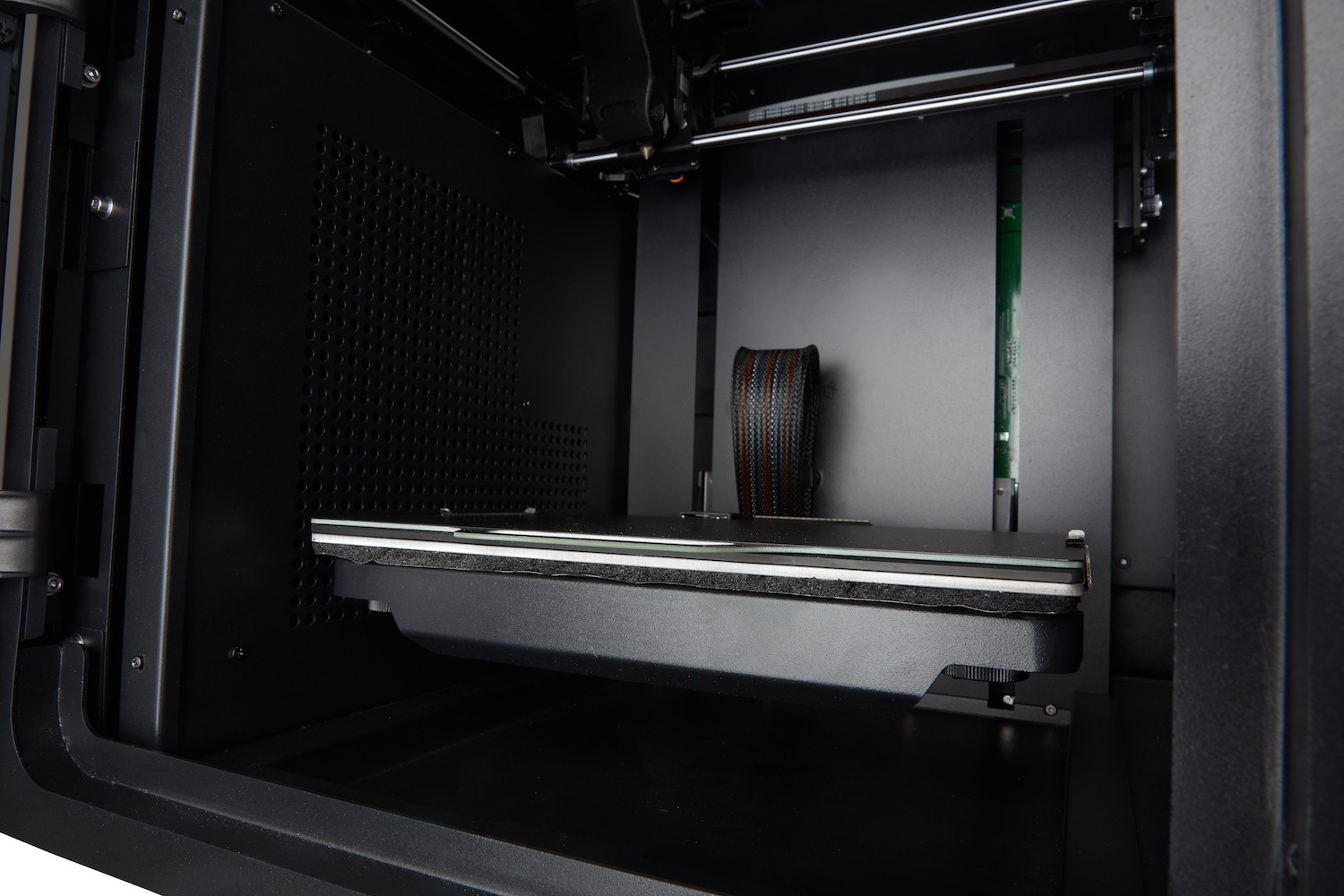

Enclosed Chamber

The build chamber is fully enclosed and drastically reduces the chance of warped prints.

Print Queue

Queue multiple prints to run after each other. This helps to speed up the printing process for schools or offices.

Engineered for success

Specialist print heads

Print with different print heads optimised for different materials, ensuring you get only the cleanest prints on your UP300 3D printer. One is for ABS and other high temperature filaments, one for lower temperature filaments such as PLA, and the other is for TPU, a flexible polyurethane.

Swap-and-go design

Interchangeable build plates

New double-sided build plate design allows you to remove prints easier due to the increased rigidity of the plates. The glass surface provides a consistent, flat base, ensuring a smooth underside of your models.

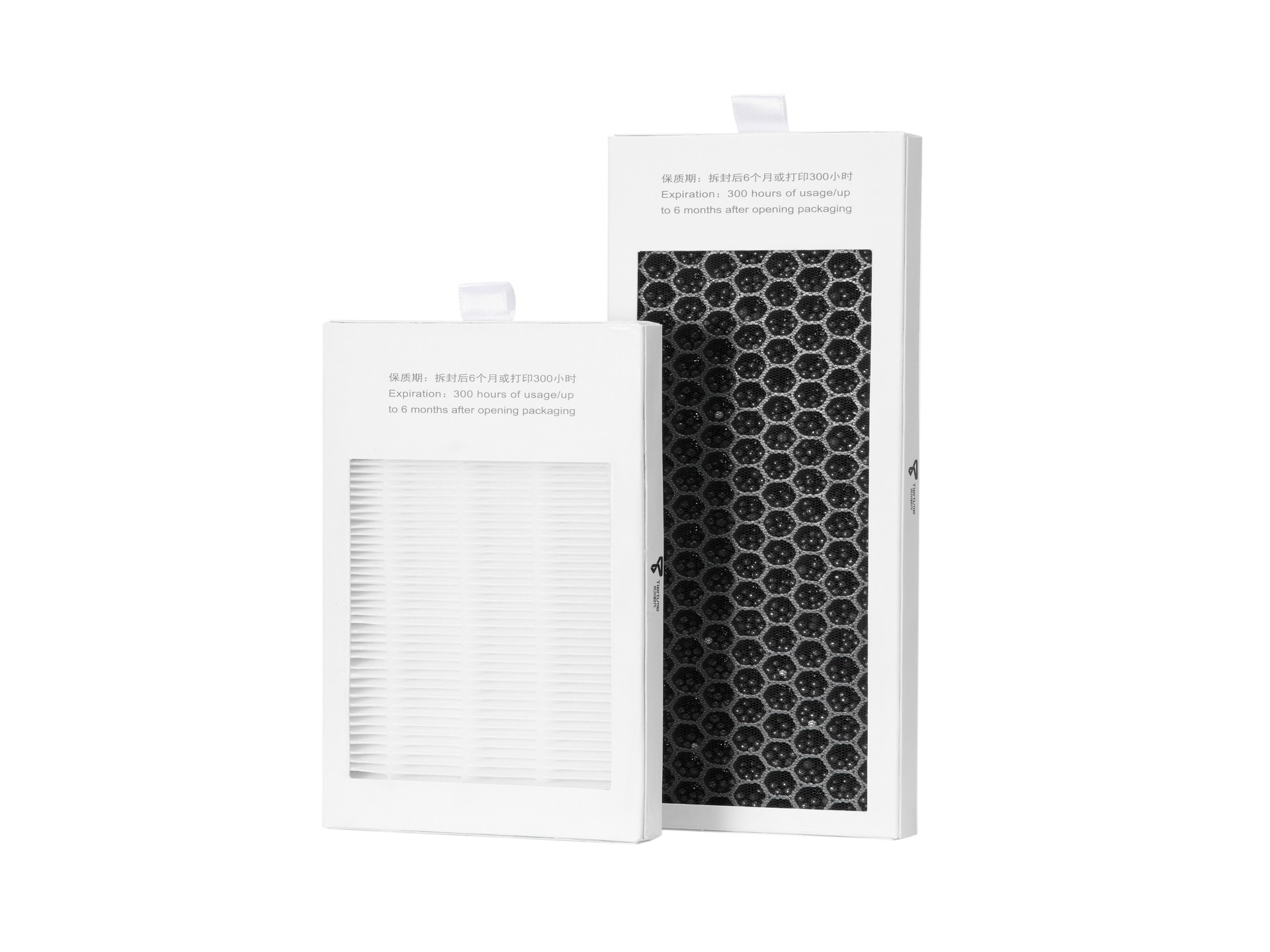

Active carbon & HEPA filters

Dual filtration systems

The UP Mini 2’s HEPA filtration system filters the air in your 3D printer, removing most of the fumes normally present during the 3D printing process. This is perfect for classroom or office applications.